The polybag challenge: reducing our reliance on single-use plastics

The polybag challenge: reducing our reliance on single-use plastics

These thin, transparent plastic bags, used to wrap individual items, are the biggest challenge for the global fashion industry. Can't we just get rid of them?

These thin, transparent plastic bags, used to wrap individual items, are the biggest challenge for the global fashion industry. Can't we just get rid of them?

Anyone who orders fashion online knows what a polybag is. These thin, transparent plastic bags, used to wrap individual items, are the biggest challenge for Zalando and the global fashion industry when it comes to avoiding single-use plastic. Can't we just get rid of them?

As a company committed to shaping a more sustainable fashion industry, Zalando is actively exploring ways to reduce the use of packaging – no matter what material it's made of – in its operations. To become more sustainable, we need to reduce our packaging volumes and move toward circular systems that reduce or eliminate waste that has to be incinerated or sent to landfill otherwise because it cannot be recycled or recovered in any meaningful way. We also have to eliminate single-use plastic, meaning packaging that is made of plastic and is not designed to be returned to the manufacturer or reused for the same purpose for which it was designed.

Easy handling and protection of items

So, why doesn't the fashion industry simply get rid of single-use plastic polybags and sell the items unpackaged? To answer that question, we need to take a look at the role of packaging: most items go on quite an adventurous journey after they leave the factory bound towards the end customer. They are produced, processed, transported and stored in warehouses until they are ordered. Changing storage conditions as well as automation technology throughout the supply chain can damage the items, which is why there needs to be a protective layer around each item. For fashion items, manufacturers usually choose polybags made of plastics because this light-weight material has been proven to shield the products against moisture, dirt, and damage during storage and processing.

However, there is another reason why each product is individually packaged. Zalando is supplied by several thousand brands and manufacturers. New goods arrive at our logistics centres almost every day. To ensure that the items reach us undamaged and can be processed immediately, suppliers have to deliver their items in a "retail ready" condition, meaning with individual packaging suitable for the sales unit to be sold to end consumers. This means that shoes, for example, have to be delivered bundled in pairs in a shoe box, as is usually the case in a store. For fashion items, plastic polybags are usually the most practical option as they are lightweight, not easily torn and transparent, which allows employees to quickly identify items or scan barcodes.

The challenging search for alternative materials

Polybags made of single-use plastic ensure products stay protected within operational processes, even if they are not necessarily the most sustainable solution. We have tested using polybags made from alternative materials such as paper for our own private label brands, However, we have found that this is often associated with higher repacking rates than plastic bags, as the paper polybags tear at different parts of the process and end up requiring an additional polybag to properly protect the item, causing additional waste. To implement a paper polybag that is fit for purpose, we would need to increase their durability and thickness, adding material and weight. We are still searching for a perfect solution that is scientifically proven to be more sustainable option.

Minimising the use of polybags

However, we are taking steps to minimise our use of polybags whenever possible, like introducing more efficient folding techniques for our Private Labels and using thinner bags for the products sold in our Fashion Store. Through these initiatives, we saved 919 metric tons of single-use plastic in 2022. In our Nordic markets, we piloted customer-facing reusable polybags with 100% recycled content. These are less likely to be damaged when opened. If customers return them to us intact, they can be used again.

Still, eliminating single-use plastics remains a key obstacle to Zalando achieving its sustainability goals. Finding the perfect solution is a complex task, especially in a landscape where more sustainable alternatives are not yet fully scalable or may not meet the minimum requirements to be a more sustainable solution. We are navigating these complexities with a focus on continuous improvement and collaboration with industry experts and our partners.

The seven Black-owned brands taking part in our Accelerator

The jury of the ADAN for Zalando Black-owned Brands Accelerator has selected seven talented brands that are taking part in the six-month upskilling programme

Acting local: our commitment to communities through volunteering

How our volunteering programme fosters personal growth, team spirit, and positive impact across local communities

Empowering Disabled children through Adaptive fashion

Parents and caregivers of Disabled kids helped Zalando to define the most sought-after Adaptive features for its very first Adaptive kidswear collection

Moving towards a more circular future

As part of its commitment to incorporating more circular business models, Zalando joins The Fashion ReModel project alongside other leading fashion companies

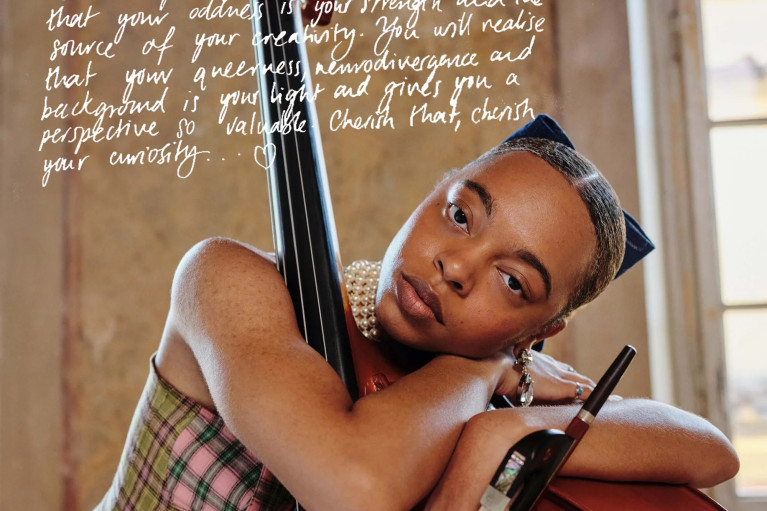

‘Their Time’ - exploring the LGBTQIA+ community’s concept of time

An insightful short film on how LGBTQIA+ people from all over Europe navigate progress at a different pace, shaped by historical and personal contexts

Adaptive Fashion Hub: functionality meets style and inspiration

Through an ever-growing collection and a unique shopping experience, Zalando strives to provide a truly inclusive journey for Disabled customers

Empowering the next generation of fashion designers

Zalando expands programme that brings circularity to the curriculum of fashion design graduates

Upskilling Black-owned fashion brands with a new accelerator

Zalando and ADAN foster diversity and innovation within the fashion industry by launching a six-month accelerator programme for small Black-owned brands